Latest News

Scientists unveil hydrogel smart window offering cooling and heat recovery

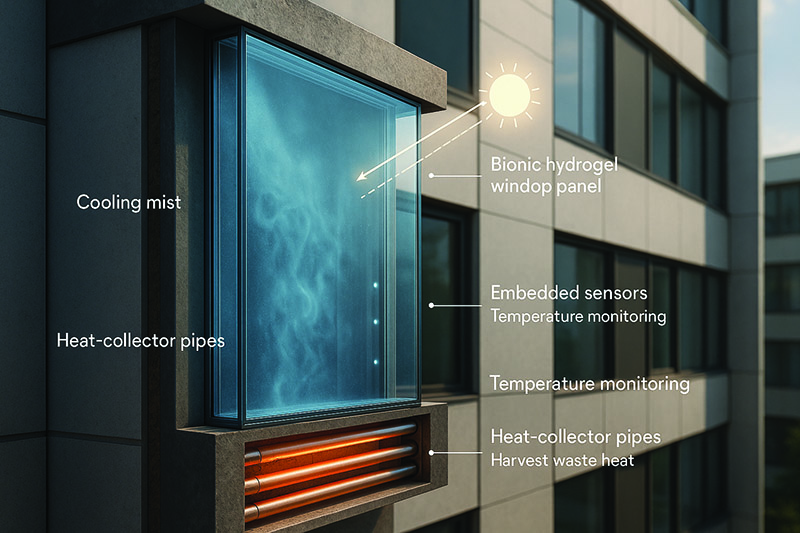

A team of researchers from Fudan University and collaborating institutes has unveiled a bionic hydrogel-based smart window system capable of sustaining sub-ambient temperatures for a record 168 hours while simultaneously harvesting waste heat for reuse. The transparent composite hydrogel, dubbed CPPB, achieves an average visible-light transmittance of 92%, blocks more than 75% of ultraviolet radiation and suppresses near-infrared transmission by roughly 30%, all without sacrificing clarity.

At the heart of the innovation lies a multilayer assembly: a thin film of CPPB hydrogel bonded to conventional glazing and a concealed water-circulation layer. During the day, the hydrogel’s thermochromic and evaporative-cooling properties enable a sustained temperature drop of approximately 22 °C below ambient temperatures, outperforming previous smart-window prototypes by a wide margin. Excess thermal energy absorbed by the system is collected via the integrated water loop, offering the potential to pre-heat domestic water or feed low-grade heat back into building systems.

Lead author Qianwang Ye explained that achieving both high transparency and prolonged cooling performance required careful optimization of the hydrogel’s polymer matrix and crosslink density. “Our composite balances water retention for evaporative cooling with mechanical robustness,” he said. “It can withstand UV irradiation and thermal cycling without significant degradation, which is essential for real-world façade applications.” Independent durability tests revealed no measurable decline in cooling efficiency after 100 cycles of simulated solar exposure.

The implications for building energy management are considerable. Windows account for up to 30% of a building’s heat gain in summer months, placing heavy demand on mechanical cooling systems. By passively maintaining lower interior surface temperatures, CPPB windows could reduce reliance on air-conditioning and trim peak electricity loads. Meanwhile, the harvested waste heat—collected at temperatures up to 60 °C—could supply domestic hot water or support underfloor heating during cooler periods, enhancing overall energy efficiency.

Despite its promise, CPPB faces hurdles before commercial deployment. Large-format coating of hydrogel layers must be scaled up cost-effectively, and long-term field trials are needed to validate performance across diverse climates. Moreover, integration with existing window frames and compliance with façade fire and safety standards will require collaboration between material scientists, glazing manufacturers and building regulators.

Industry observers note that the CPPB system’s combination of cooling and heat-recovery functions distinguishes it from other smart-window technologies focused solely on light modulation. “This represents a significant step forward,” said Dr. Helen Carter, an independent façade engineer. “The dual functionality addresses both peak-load reduction and utilisation of what would otherwise be wasted thermal energy.”

As global building sectors seek to meet stringent energy and carbon targets, the CPPB hydrogel window could play a key role in decarbonising the built environment. The research team is now engaging with glazing fabricators to pilot prototypes in commercial offices in Shanghai and Europe later this year. If successful, the technology may herald a new generation of smart façades—ones that not only regulate light and heat but also actively harness energy for on-site reuse.