Future-proof machinery investment at Quickslide’s Brighouse factory

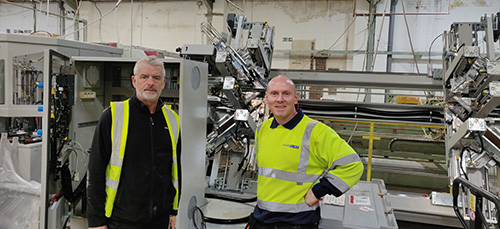

Quickslide’s Brighouse factory has recently seen the addition of two URBAN corner cleaning machines and two quad welders following an investment of £350,000 in its factory infrastructure.

A leading manufacturer of made-to-measure sliding sash windows, bi-folding doors, casement windows and doors in PVCu and aluminium, Quickslide says the spend is part of a £2m investment plan which spans 12 months. This centres around increasing capacity while improving quality and efficiency.

URBAN machines are known for their machining quality and excellent precision and, says Quickslide Managing Director Ben Weber, will increase throughput at key points of the company’s fabrication process. The robust quad welders ensure reliability and repeatability while the corner cleaning machines allow efficient processing and cleaning of window profile after the welding cycle.

Ben affirmed how much Quickslide has grown over the last decade and how the fabricator is now manufacturing close to 1,000 windows a week.

He explained: “We have installed the Schirmer ‘Rolls Royce’ of cutting centres and machinery like this is certainly something that we needed to make the appropriate level of investment in. We have already made huge strides in system and product innovation and this latest step is all about future-proofing the business for the next five to ten years.”

Chairman Adrian Barraclough added: “Quickslide is constantly looking at ways to remain at the forefront when it comes to technology and the advancements in product variety and quality it offers. By ensuring that we continue with regular investments in high quality, modern machinery means that our customers will always be able to expect the finest quality products, for the right price, delivered within a sensible timeframe.

“Our investment reinforces our belief that British manufacturing is some of the best in the world. We’re as proud of that as we are of our award-winning products.”